Product categories

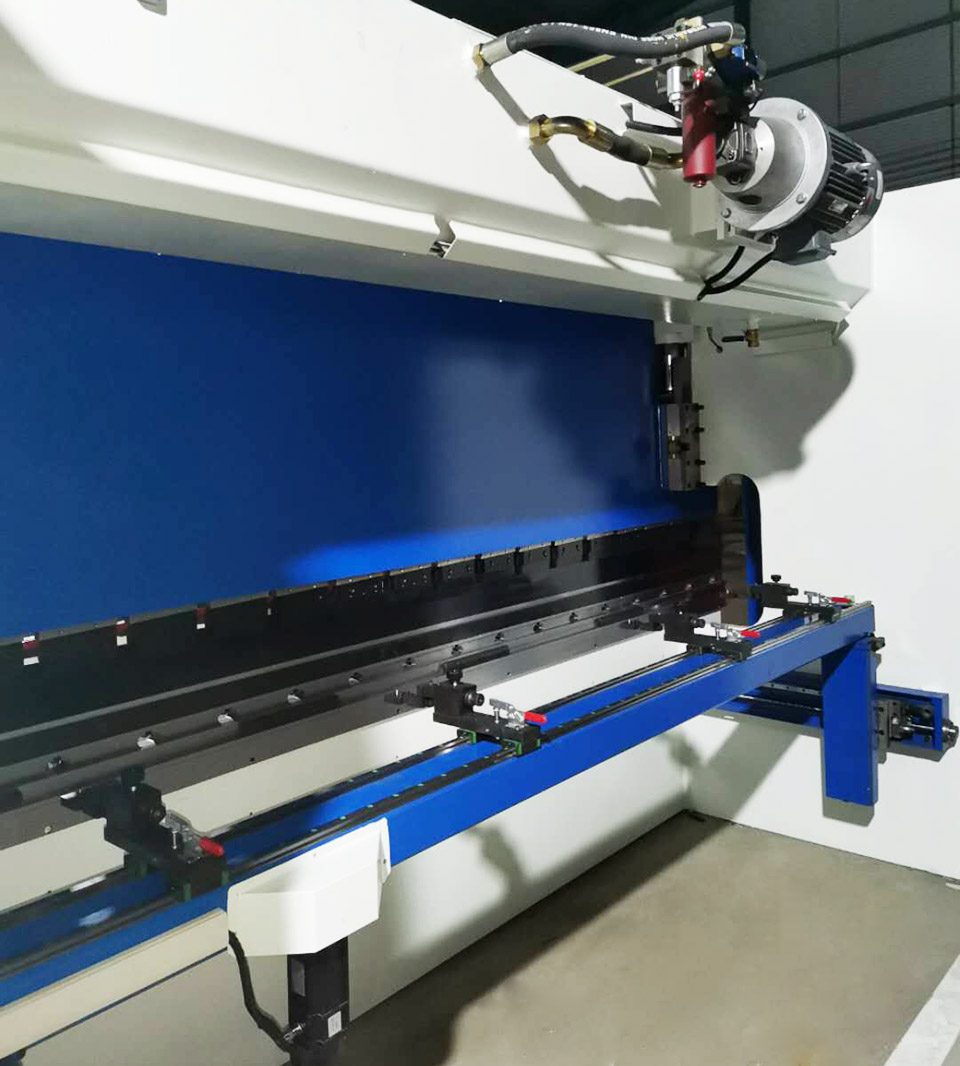

Home > Product display > WE67K Electro Hydraulic Servo CNC Press Brake

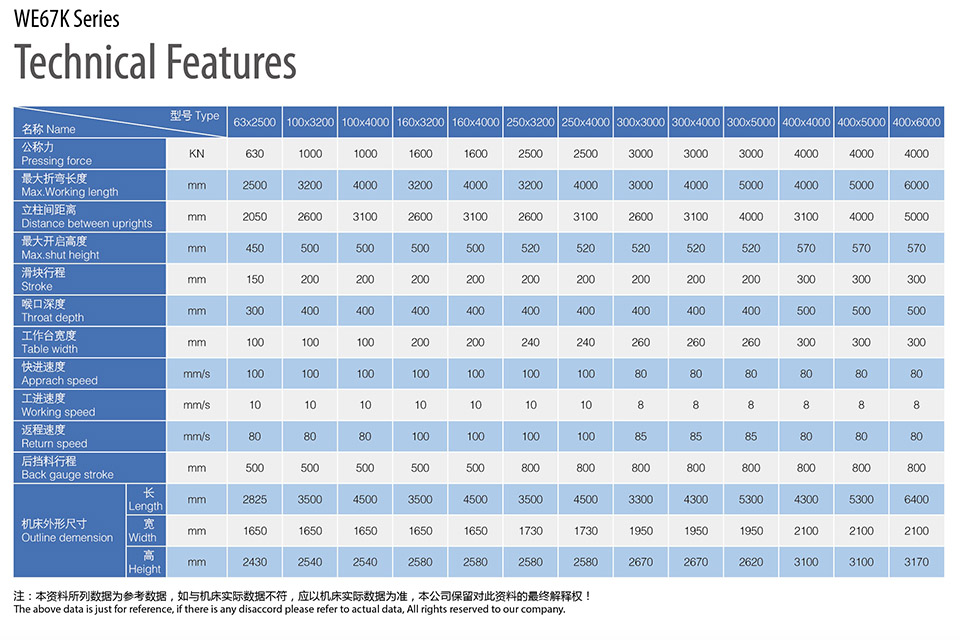

Technical parameter | ||

Machine model | WE67K-110T/4100 | |

Nominal force | 1100KN | |

Table length | 4100mm | |

Table width | 100mm (The lower die is a double V-shaped concentric die) | |

Distance between columns | 3100mm | |

Throat depth | 400mm | |

Slider stroke | 200mm | |

Maximum opening height | 450mm | |

Slide fast down speed | 120mm/s | |

Slider return speed | 100mm/s | |

Slider working speed | 10mm/s | |

Main motor power | 7.5KW | |

Numerical control system | DA53T | |

Number of control axes | 4+1(Two axes of oil cylinder, front and rear axis of rear stop, lifting r axis + compensation axis) | |

X-axis stroke of rear stop | 500mm | |

X-axis speed of rear stopper | 200mm/s | |

Thickness of wallboard, sliding block and worktable | They are 50mm, 60mm, 60mm | |

Dimensions | 4200×1750×2520mm | |

Weight about | 8.5T | |

Main configuration list | ||

Control system | 1set | Netherlands DELEM DA53T(4+1)system |

Servo motor and driver | 1set | Shenzhen |

Hydraulic system | 1set | Germany |

Ball screw | 2 | Taiwan ABBA |

Linear guide rail | 2 | Taiwan ABBA |

Connector | 1set | Germany EMB |

Seal ring | 1set | Japan NOK |

Grating ruler | 2 | Italy GV |

Main electrical components | 1set | Schneider |

Main uses and product features

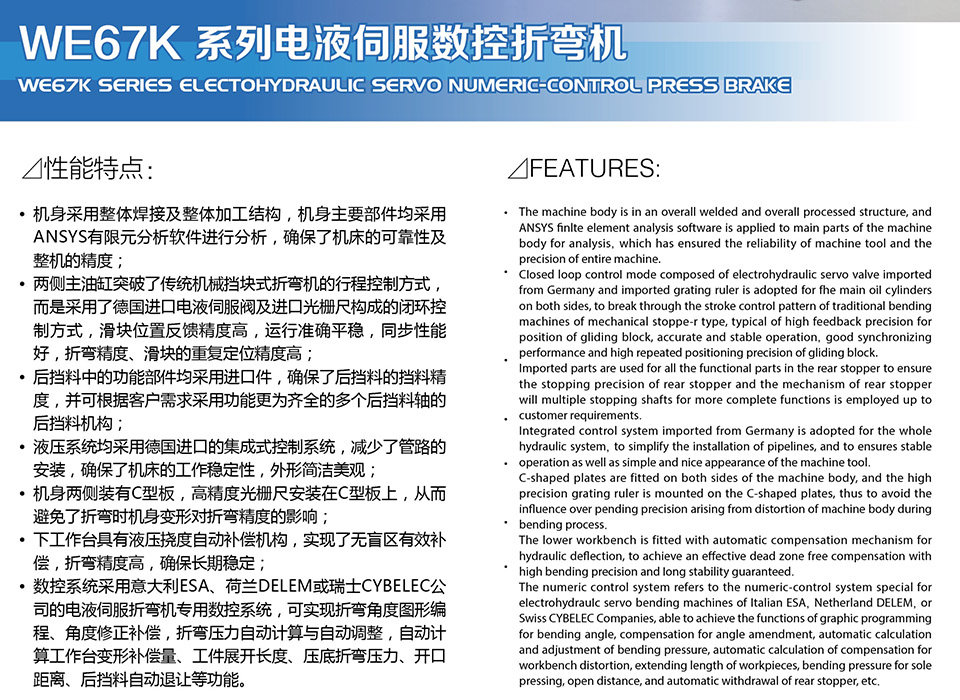

WD67K series electro-hydraulic servo numerical control bending machine integrates numerical control technology, servo and hydraulic technology in one, the slide is through the action of the control valve to achieve periodic ground and down movement, movement measurement is through the grating reading measurement on both sides of the machine tool.

The DNC controls the openings of the two valves in the left and right cylinders, and if needed, the flow in the cylinder can be redistributed by the servo valve to move the slider vertically and in a straight line. The amount of movement is determined by the number of newly measured pulses.

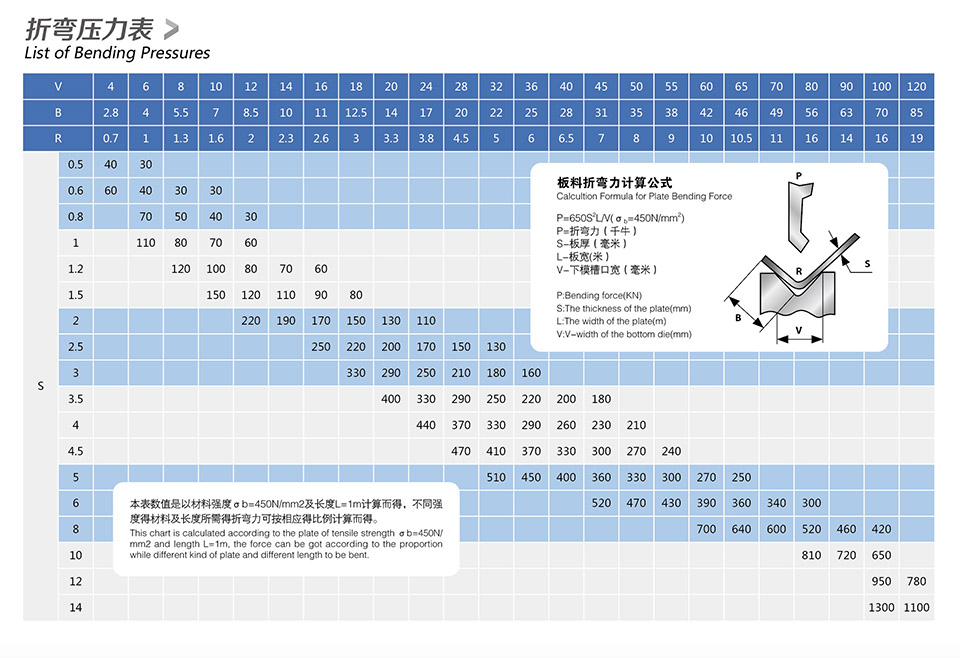

Electro-hydraulic servo CNC bending machine folded sheet metal bending has high productivity and high working accuracy, when bending different thickness of sheet metal, should choose to die under the opening on the distribution of different size of the "V" shaped groove, "V" shaped groove opening size generally should be more than 8 times the sheet thickness, if different shape of the upper and lower mould, can be bent into various shapes artifacts, at the same time by sheet metal bending force table (see machine) or bending formula to calculate the bending force. Slider stroke can be a plate bending forming, after many bending can obtain more complex shape of the workpiece.

Electro-hydraulic servo CNC bending machine adopts steel plate welding fuselage, with sufficient strength and rigidity, hydraulic transmission guarantee work, has the automatic overload protection, in addition, this machine has the stable work, convenient operation, safe and reliable, etc, this machine is fitted with deflection compensation, compensation when bending sheet metal workbench and deflection of the stress of the sliding block, ensure the high working accuracy.

The machine adopts advanced electro-hydraulic servo automatic control system, accurate positioning of the slider, smooth operation. Slider stroke and position can be adjusted and set according to the needs of the bending process, and has the action specification such as point moving, which is convenient for mold testing and adjustment.

This machine is one of the ideal sheet metal forming equipment with advanced technology and reliable performance. It is widely used in aircraft, automobile, shipbuilding, machinery and other operations with high production efficiency.

Technical characteristics

1. The main oil cylinder on both sides adopts imported electro-hydraulic servo valve and imported grating scale to form closed-loop control, with accurate feedback and accurate running of the slider, thus high bending accuracy and repeated positioning accuracy of the slider. Deviation of 0.05 mm or less.

2. Repeated positioning accuracy of rear stopper is less than or equal to 0.05mm. Functional parts of rear stopper adopt national or imported parts to ensure the stopper accuracy of the machine.

3. The fuselage adopts split steel plate welding structure. After vibration aging treatment, the deformation caused by welding stress and processing stress can be removed to ensure the accuracy and stability of the machine tool.

4. The fuselage, slider and other important parts are analyzed and made by finite element analysis software, which can ensure the working stability of the machine tool.

5, The hydraulic system adopts the imported integrated control system, reduces the pipeline installation, improves the working stability of the machine tool, beautiful and simple appearance.

6, CNC system adopts the Netherlands DELEM DA52S system.

7. C-shaped plates are installed on both sides of the fuselage, and high-precision grating ruler is installed on the C-shaped plates, so as to avoid the influence of bending deformation on bending accuracy.

8. Oil cylinders processed by professional manufacturers, complete sets of imported seals, and pipe joints imported from Germany EMB overcome oil leakage.

Nanjing Mavo Machine Tool Manufacturing Co., Ltd

Contact person: Wilson Wang / Danny Wu

Mobile phone: +8613276628018 / +8615722753754

Email:Wilson@mavomt.com / Danny@mavomt.com

Address: Dongshan Avenue, Economic development Zone , Jiangning District,Nanjing, Jiangsu Province,China