Product categories

Home > Product display > QC11K Hydraulic Guillotine shearing machine

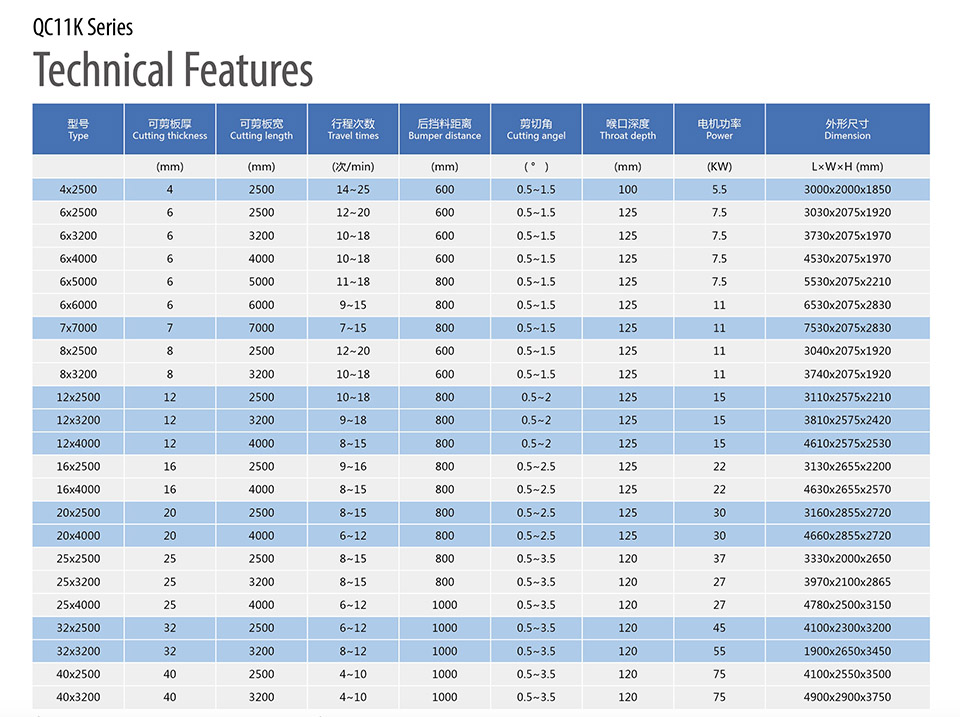

Main technical parameters | ||

Maximum shear thickness: | 20mm | |

Maximum shear width: | 2500mm | |

Thickness of worktable panel: | 60mm | |

Thickness of wallboard: | 60mm | |

Thickness of tool carrier vertical plate: | 60mm | |

Strength of the plate to be cut: | 450N/mm2 | |

Shear angle: | 0.5°~2.5° | |

Maximum distance of back stop: | 750mm | |

Number of trips (approximately): | 5-10 second/min | |

Throat depth: | 130mm | |

Blade length: | 2600mm | |

Main motor: | Y200L-4 n=1440r/min N=30KW | |

Rear stop motor: | RV040 1:10 n=1440r/min N=0.37KW | |

Gear pump: | G63F | |

Dimensions: | Length × width × height=3300×2100×2500mm | |

Weight about: | 12.00 tons | |

Accessory Factory | ||

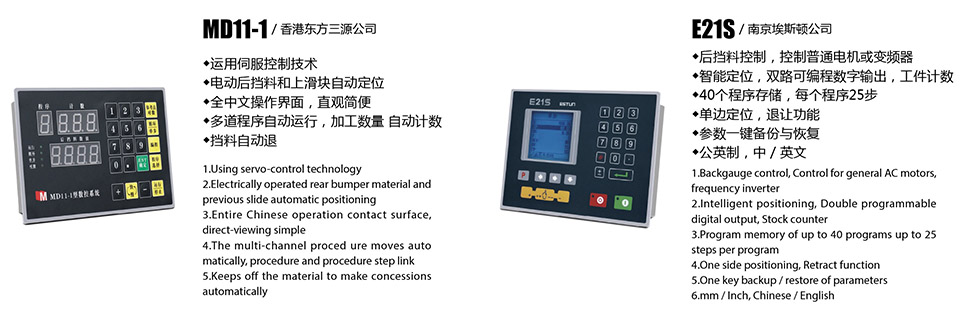

Control system: | MD11-1(Hong Kong Sanyuan) | |

Main electrical components: | Chint electric | |

Valve block: | Gold oil pressure | |

Cylinder: | Anhui Huayi | |

Oil pump: | Shanghai | |

Ball screw: | ABBA、TBI | |

linear guide rail: | ABBA、TBI linear guide rail | |

Sealing element: | Taiwan Dingji, Japan NOK | |

Electric machinery: | Shanghai Huyuan | |

Product configuration

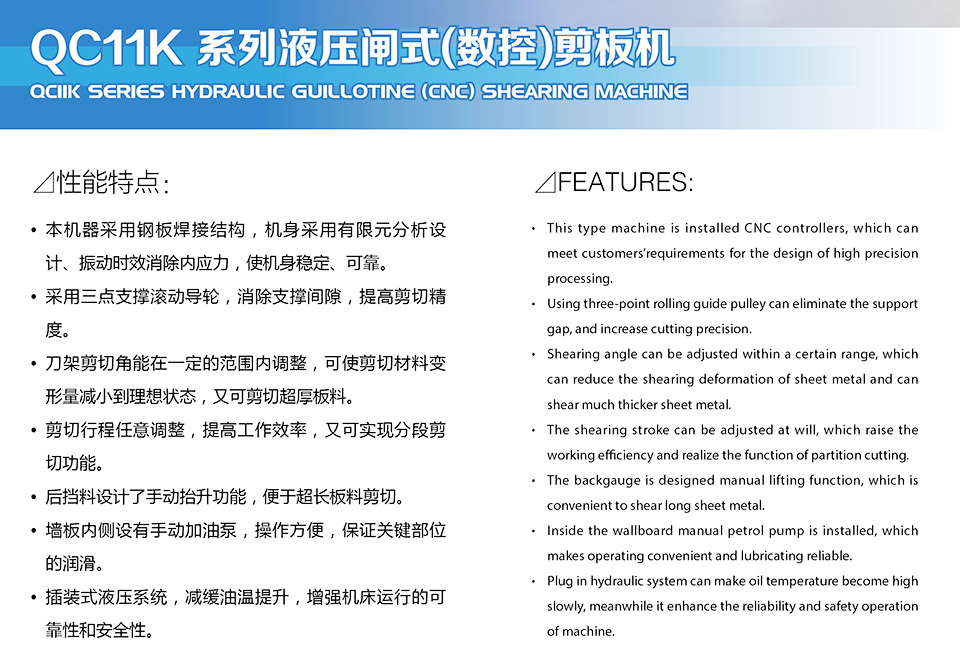

1. The second generation of hydraulic gate shears is an ideal replacement product of hydraulic pendulum shears. The double cylinder series structure and all steel structure are designed and manufactured with beautiful appearance and reliable structure.

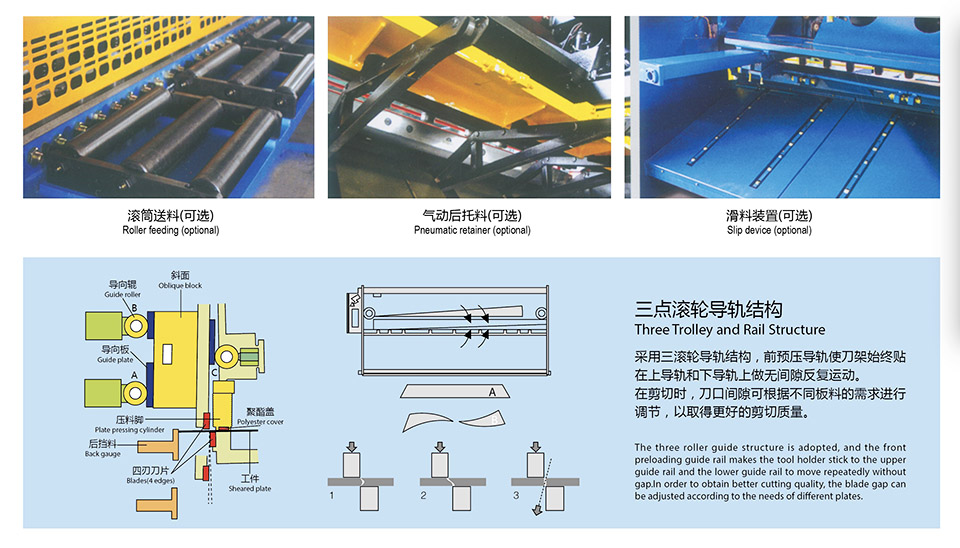

2. The front supporting material is composed of three groups of rollers, which can be easily adjusted and transported.

3. Using UG (finite element) analysis method, through computer-aided optimization design. Super strong steel structure design, so that the fuselage in full load use time-varying table is very small, to ensure the durability of the blade.

4. The whole Q235 steel plate welding structure has good strength, rigidity and vibration resistance. The two cylinders are fixed on the left and right columns. The worktable is equipped with an auxiliary knife seat, which is convenient for micro adjustment of the blade. The worktable is also equipped with a feeding roller, which is easy to operate.

5. Vibration aging technology is used to eliminate internal stress. The whole frame is derusted by sand blasting and sprayed with antirust paint.

Main performance characteristics

1. The adjustment of blade clearance is controlled by worm gear to meet the shear needs of different plate thickness and materials.

2. The adjustment of the cutting angle of the tool holder is controlled by the button on the operation panel, which can be adjusted in the range of 0.5 ° to 2.5 ° to reduce the deformation of the cutting material to the ideal state. The hydraulic electric control stepless adjustment of the cutting angle: the cutting angle increases, the cutting capacity increases (it can be appropriately overloaded), the cutting angle decreases, and the cutting speed increases.

3. The adjustment of the back stop is driven by the worm gear reducer motor, which ensures the accuracy of the back stop (≤± 0.10 mm) and the accuracy and convenience of the LCD display.

4. The upper tool rest adopts 1 ° rake angle, which is not only convenient for blanking, but also improves the geometric accuracy of parts.

5. The upper and lower blades can be sheared with four cutting edges and made of high-quality 9CrSi material, which improves the wear resistance and service life of the blade.

6. The shearing stroke can be adjusted at will, which not only improves the work efficiency, but also realizes the segmented shearing function. The LCD display is accurate and convenient,.

7. Cutting times with automatic counting, fixed number function, reduce the tedious counting work, LCD display.

8. The three-point support rolling guide is adopted to eliminate the support gap and improve the shearing accuracy;

9. The clearance of the cutting edge is adjusted electrically and displayed on the digital display panel;

Hydraulic system

The hydraulic system consists of oil pump, oil manifold, hydraulic valve, oil cylinder and nitrogen accumulator. It can compress the sheet metal, shear, adjust the shear angle, charge the accumulator, and return the tool holder quickly.

1. The advanced integrated hydraulic system is adopted to reduce the pipeline installation, slow down the oil temperature rise, and ensure the high reliability and safety of the machine tool operation.

2. The imported seal overcomes the leakage of pipe joint and oil cylinder.

3. The hydraulic pressing mechanism is adopted. After several pressing oil cylinders installed on the support plate in front of the frame are fed with oil, the pressing head presses down to compress the plate after overcoming the tension of the tension spring. After the shearing is completed, it is reset by the tension of the tension spring. The pressing force increases with the increase of the thickness of the sheared plate.

Electrical system

The electrical part of the machine tool is designed according to the national standard mechanical safety mechanical electrical equipment Part 1: General technical conditions. The machine control system adopts relay logic control.

The electric box of the machine tool is located on the left side of the machine tool, which controls the power supply of the whole machine. The operating elements of the machine tool, except the foot switch, are all concentrated on the console (button box) in front of the machine tool. The function of each operating element is marked by the image symbol above it.

1. Machine tool power supply

Power supply voltage:

Power circuit: three phase, 380VAC, 50Hz

Main control circuit: 220 VAC, 50 Hz

Control circuit of material retaining frame: 220 VAC, 50 Hz

Solenoid valve circuit: 24 VDC

Signal lamp circuit 6vac, 50Hz

The main power supply is controlled by the main switch (automatic air switch QF1) installed on the side of the electrical cabinet. QF1 with shunt trip coil. When the door of the electrical cabinet is opened, the shunt trip coil is powered on, and the automatic air switch QF1 trips to cut off the power supply, so as to realize the door opening and power-off protection.

2. Safety protection of machine tools

1. Power protection: for the protection of the whole equipment and its power line, it is recommended that the user use 100A air circuit breaker.

2. Short circuit and overload of oil pump motor are protected by air switch QF1.

3. The short circuit and overload of the motor of the material retaining frame and the motor of the gap adjustment are protected by the air switch QF2.

4. The primary side of control transformer TC is protected by circuit breaker QF3, and the secondary side is protected by circuit breakers QF4, qf5 and QF6.

5. The front and rear limits of the material retaining frame and the gap adjustment limits are protected by the travel switch, and there are also soft limits in the system.

6. Press the emergency stop button, the machine will stop all movement immediately.

Nanjing Mavo Machine Tool Manufacturing Co., Ltd

Contact person: Wilson Wang / Danny Wu

Mobile phone: +8613276628018 / +8615722753754

Email:Wilson@mavomt.com / Danny@mavomt.com

Address: Dongshan Avenue, Economic development Zone , Jiangning District,Nanjing, Jiangsu Province,China